Decades ago, the semiconductor silicon material has been leading the way in the field of power semiconductor devices. However, with the urgent need for miniaturization, high frequency, high temperature, high voltage and radiation resistance in the power field, silicon-based power devices have reached their theoretical limit. Second generation semiconductor materials such as Gallium Arsenide (GaAs), Silicon Carbide Power Devices (SIC), Gallium Nitride (GAN), Aluminum Nitride (AlN), Zinc Oxide (ZnO), Silicon Carbide (SIC), Silicon Carbide (GAN), Aluminum Nitride (AlN), Zinc Oxide (ZnO), Silicon Carbide (ZnO), Silicon Carbide (SIC), Silicon Carbide (GAN), Aluminum Nitride (AlN), Zinc Oxide (ZnO), Silicon, Third-generation semiconductor materials such as diamond (with a band gap greater than 3.2 eV) have already entered the semiconductor stage.

Compared with the first-generation semiconductor material silicon and the second-generation semiconductor material gallium arsenide, silicon carbide has a wide band gap (2.9 times that of silicon), a high critical breakdown electric field (10 times that of silicon), and a high thermal conductivity ( It is 3.3 times that of silicon), the carrier saturation drift speed is high (1.9 times that of silicon), and its chemical stability and thermal stability are good. It is an ideal material for power electronics and optoelectronic devices. Under the same breakdown voltage, the on-resistance of SiC-based power devices is only 1/200 of that of silicon devices, which greatly reduces the turn-on loss of the converter. According to statistics, if the whole country adopts silicon carbide power electronic devices for power transmission, the annual power saving can be equivalent to the power generation of two Three Gorges Hydropower Stations. According to the research of American Corey Corporation, if silicon carbide power devices are widely used in the world, it can save 35 billion US dollars of energy every year. Therefore, silicon carbide-based power devices will be able to greatly reduce energy consumption and meet the requirements of future power systems for high-voltage and low-power power electronic devices.

With the development of SiC substrate, epitaxial growth and process technology, SiC Schottky Barrier Diode (SBD) and Power Metal Oxide Semiconductor Field Effect Transistor (MOSFET) with moderate blocking voltage (600-1700v) are gradually commercialized . However, the impact of material properties and material defects on the performance and reliability of SiC power devices is not fully understood, especially for large-capacity SiC power devices above 10kV, SiC thick-film epitaxial materials are usually required. The uniform epitaxy of high-quality SiC with high thickness and low defects directly determines the performance of SiC-based power electronic devices. Secondly, the biggest challenge faced by SiC-based insulated gate bipolar transistors (IGBTs) is the low carrier mobility (10cm2/VS), which is only 1/10 of that of SiC-based MOSFETs, and is lower than that of SiC bulk materials (1000cm2/VS). ) are two orders of magnitude lower. Carrier mobility determines the conductivity and operating frequency of a semiconductor device, and affects the switching loss and efficiency of the device.

Currently, SiC-based power devices face severe challenges. Existing SiC-based Schottky diodes, mosfets and other devices cannot effectively meet the needs of practical applications. The demand for IGBT devices is increasingly urgent. We must break through the bottleneck problem in SiC-based IGBT research, improve device voltage strength, and improve channel mobility. In response to these core technical problems, the research group of the Institute of Semiconductors, Chinese Academy of Sciences started from the most basic scientific laws to determine the carrier mobility of SiC-based IGBTs, revealed the carrier transport mechanism and the alignment of the energy band structure, and grown high-quality The silicon carbide thick film epitaxial material and low interface state gate dielectric layer material were studied and controlled, and the silicon carbide IGBT device with high carrier mobility and high blocking voltage was developed.

The growth of SiC thick epitaxial layers is one of the foundations for the development of high-voltage and large-capacity IGBT devices. Thicker epitaxial layers and lower background carrier concentration are the guarantees of the breakdown resistance of SiC devices. Therefore, the research group studied the temperature field and flow field distribution under fast epitaxial growth conditions, established the internal relationship between the growth rate of silicon carbide and process conditions, and adopted a hot-wall CVD reaction growth chamber to improve the uniformity of the temperature field of the silicon carbide CVD system. At the same time, the low-pressure chemical vapor deposition method can adjust the flow rate of the reactive gas and change the growth temperature, thereby increasing the growth rate of SiC epitaxy and ensuring a constant carbon-to-silicon ratio, so that the composition of SiC epitaxy remains constant while growing rapidly.

In the development of silicon carbide IGBTs, spherical and cylindrical junctions are formed around the device using an ion implantation doping process. Therefore, it is necessary to design an effective terminal structure to improve the breakdown capability of high-voltage SiC devices. Commonly used structures in SiC termination technology include junction termination extension (JTE), field confinement ring (GR), field plate, etc. The research group adopts ssm JTE termination structure, which effectively improves the resistance of device blocking voltage to doping concentration. It can greatly reduce the leakage current of the device at 10kV. The leakage current of SiC-IGBT at 10kV is only 10na. The large-capacity SiC IGBT devices developed by the research group can be applied to a new generation of smart grids to further optimize the power distribution system, making the power grid operate more efficiently and switch faster, especially for long-distance transmission lines. Using this silicon carbide device can reduce the power consumption by half, thereby reducing the heat generation of the power equipment, greatly reducing the volume and weight of the power converter, which is very beneficial to the power system with an operating temperature of up to 200°C.

It is reported that in 2010, the world's average electricity consumption accounted for about 20% of the total energy consumption, and this proportion has grown rapidly in recent years. Power semiconductor devices are indispensable devices for power regulation. The research results of the research team will play an extremely important role in high efficiency and energy saving. In the next step, the research group will continue to deepen research, provide scientific research assistance for comprehensively improving the original innovation capability of my country's fully controlled power electronic devices, and enhance my country's international competitiveness in this strategic field.

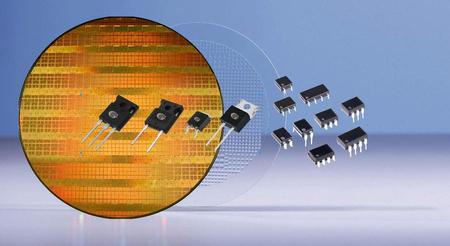

Wuxi Guojing Micro Semiconductor Technology Co., Ltd. is a high-tech innovative enterprise engaged in the R&D and industrialization of wide-bandgap third-generation semiconductor silicon carbide SiC power devices, gallium nitride GaN optoelectronic devices and conventional integrated circuits. Chip design, production and sales of silicon carbide Schottky diodes, GaN optocoupler relays, single-chip integrated circuits and other products, and provide overall solution design supporting services for related products. There are R&D centers and sales service support centers and offices in Shenzhen and Hong Kong.

The company has domestic leading R&D strength, focusing on providing customers with high-efficiency, low-power, low-resistance, stable-quality silicon carbide high and low-power devices and optoelectronic integrated circuit products, as well as one-stop application solutions and on-site technology. Support services that make customers' systems performant, flexible, reliable, and cost-competitive.

The company's silicon carbide power devices cover 650V/2A-100A, 1200V/2A-90A, 1700V/5A-80A and other series. The products have been put into mass production, and the products can fully match the advanced quality and level of international brands. It has successively launched silicon carbide Schottky diodes with full current and voltage levels, and silicon carbide MOSFET series products that have passed industrial-grade and automotive-grade reliability tests. , smart grid, high-frequency welding, rail transit, industrial control special power supply, national defense and other fields. Due to its high-speed switching and low on-resistance characteristics, it can exhibit excellent electrical characteristics even under high temperature conditions, greatly reducing switching losses, making components smaller and lighter, more efficient, and improving overall system reliability. , which can increase the cruising range of electric vehicles by 10%, reduce the weight of the whole vehicle by about 5%, and realize safe and stable operation in the high temperature environment of the designed charging pile.

Especially in the field of high and low voltage optocoupler semiconductor technology, it has an industry-leading R&D team. It has pioneered the design and development of 28nm photosensitive grating switch PVG chip technology in China, and successfully mass-produced optocoupler relay chips applied to 60V, 400V, 600V high and low voltage, low internal resistance and low capacitance, covering 1500kVrms SOP ultra-small package and 3750kVrms isolation Enhanced conventional SMD, DIP and other different packages, single, dual, mixed dual, normally open and normally closed circuit products, including 200V SOI MOS/LIGBT integrated chips, 100V CMOS/LDMOS integrated chips, 8bit and 32bit microcontrollers, etc. Integrated circuit products have been recognized as new products by the market and key scientific research units and testing institutions.

Most of the engineers in the company's core R&D team have a master's degree or above, and many doctors preside over the development of the project. The company has established a standard system for scientific and technological innovation and intellectual property management, and has accumulated many core technologies in circuit design, semiconductor device and process design, reliability design, device model extraction, etc., and has a number of international and domestic independent invention patents.

"The most important weapon of the country, starting from crystal, self-improvement and self-reliance, and achievement of a century" is the corporate goal of Guojing Microsemiconductor. We provide employees with wonderful development space and provide customers with excellent products and services. We sincerely look forward to working with you to win the future. .

© 2022 GDSiCSemi CO.,LTD copyright.